EVERY WEEK WITH A MINERAL

۰۳-بهمن-۱۳۹۶ایزوترم ( سبوس برشته )

۰۹-بهمن-۱۳۹۶

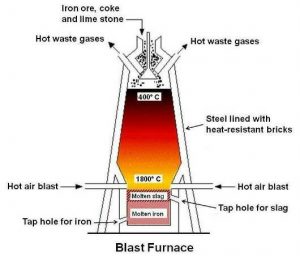

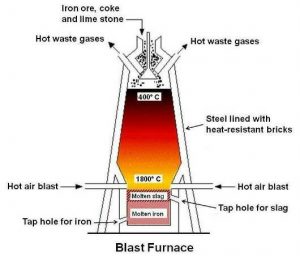

Steel Furnace Slag is produced in a (BOF) Basic Oxygen Furnace or an (EAF) Electric Arc Furnace. Hot iron (BOF) and/or scrap metal (EAF) are the primary metals to make steel in each process. Lime is injected to act as a fluxing agent

The lime combines with the silicates, aluminum oxides, magnesium oxides, manganese oxides and ferrites to form steel furnace slag, commonly called steel slag

Slag is poured from the furnace in a molten state. After cooling from its molten state, steel slag is processed to remove all free metallics and sized into products

Basic Oxygen Furnace (BOF) : Oxygen is blown into the furnace vessel through a water-cooled oxygen lance oxidizing carbon and the other unwanted elements in the molten iron. Fluxes are added to remove other unwanted elements yielding high quality steel

Electric Arc Furnace (EAF) : Charged material is heated to a liquid state by means of an electric current. The electricity has no electrochemical effect on the metal making it perfectly suited for melting scrap

Steel slag is processed as an air-cooled material. The free metallics are magnetically separated and sized into construction aggregates, used as an agricultural soil amendment, as a raw ingredient in Portland cement production, as an environmental remediation material and other uses

BITUMINOUS PAVING : Steel Slag has evolved as an ideal aggregate in Hot Mix Asphalt (HMA) surface mixture applications. Where friction is an important safety consideration in pavement design for the motoring public, properties of Steel Slag qualify it as a premier surface aggregate for skid resistant applications

With the development and implementation of Superpave technology throughout the United States as well as the further expansion of Stone Matrix Asphalt (SMA) mixes for severe traffic and axle-loading applications, Steel Slag has earned the distinction as a premium surface aggregate. In addition, Steel Slag continues to be recognized as a standard for use in both Seal Coating and Cold Patching applications

CHIP AND SEAL : Also known as “Chip Seal” or “Aggregate Seal Coating”, this is a single or double application of Bituminous Surface Treatment applied to existing pavement surfaces

The primary purpose for Chip and Seal is to achieve a skid resistance on rural pavements and to maximize driving safety for the general public. The use of Chip and Seal is a cost effective way to improve the safety and integrity of a road surface in low traffic environments